SENONGTECH

Product Introduction

Senong Tech believes that creative thinking is the key to the best service.

A reliable company by your side

We create the best products to advance to the center of the world.

Cutting & Dry Type Rice Washing Machine

Rice Washing Machine that washes rice with air.

This is an eco-friendly Air-Shock Cutting & Dry Type Rice Washing Machine that washes rice with air. It precisely and cleanly removes residual bran from the surface of white rice with high-pressure air, prevents water pollution by not using water, and is effective at energy saving.

Introduction to Cutting & Dry Type Rice Washing Machine

- Images of the rice washing equipment

Cutting dry semiconductor function

Water pollution prevention and rice washing

Rice washing for making rice cake

Rice washing for making coated rice

Rice washing for making rice flour

Rice washing for making Malgeolli (Korean rice wine)

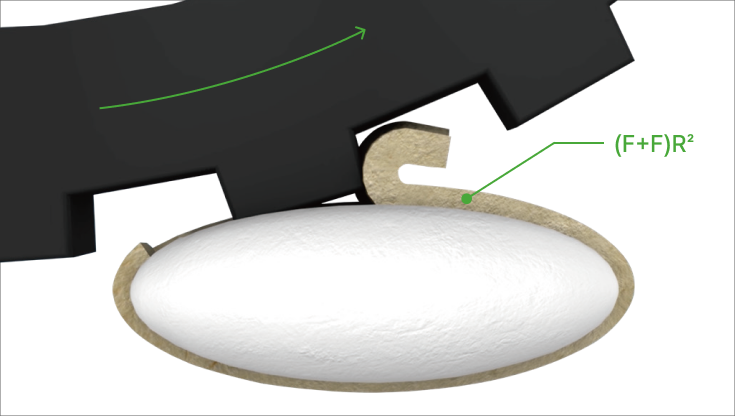

Principle of the Cutting & Dry Type Rice Washing Machine

- The machine uses cutting blades to remove fine residual bran from the surface of white rice and washes the rice with high-pressure air, using a dry rice washing technology.

- It is developed as a dry washing technology that cleans the surface of white rice, compared to the friction-based wet polishing method of scraping the white-rice surface.

- The principle of scraping off the residual bran from the surface of white rice

- Cutting and Dry Washing Method -> More power savings than existing methods

Need for Improvement in Wet Type Rice Washing Method

- Washing the 2-3% fine residual bran on the surface of white rice with water results in rice water.

- This rice water contains a high level of phosphorus (P), a major cause of river pollution. The eutrophication leads to algal blooms and water pollution.

- To purify this polluted water, a large amount of purifying agents is required. Due to rapid growth in large-scale food service operations, the volume of rice water is on the sharp increase.

- The government raises purification standards and seeks measures to prevent water pollution.

Expectancy Effects of the Cutting & Dry Type Rice Washing Machine

- The dry rice washing method, which is used to remove fine bran on the surface of white rice with the use of cutting blades and high-pressure air, minimizes rice water generation, reduces water usage, and prevents water pollution effectively.

- The bran removed from the surface of white rice can be used as a raw material for mushroom cultivation and feedstuff, contributing to a circular eco-friendly compost system.

- Bran, which causes rice water as a major culprit of river pollution, can be collected and sold. Therefore, it generates revenue of over 250 KRW per kg and contributes to business management.

- The cutting and dry type rice washing process is more cost-effective in environmental pollution prevention than wet type rice washing process, and is excellently effective at water pollution control.

Applications of the Cutting & Dry Type Rice Washing Machine

- The export of K-food led to the development of large rice cake and Tteokbokki production plants, and to the rapid rise in rice water at large-scale food service places. Accordingly, it is urgent to come up with measures to prevent environmental pollution.

- With the government's push for flour alternatives such as rice flour, the use of cutting & dry type rice washing machines is on the rapid increase.

- Domestic Makgeolli factories and brewing facilities using rice require the introduction of dry type rice washing equipment to prevent environmental pollution.

- In countries where long-grain rice (Indica type) is a staple food, the growth of the food service industry led to the increase in large-scale food service operations, requiring dry type rice washing machines.

Specifications of the Cutting & Dry Type Rice Washing Machine

| Model | Capacity (ton/hour) | Size (W x L x H) | Power Consumption (Kw) Machine | Power Consumption (Kw) Blower |

|---|---|---|---|---|

| SNC-1000 | 0.5~1 | 750x1200x1600 | 15+3 | 5 |

| SNC-2000 | 2~2.5 | 850x1300x1600 | 30+3 | 10 |

Specifications are subject to change without prior notice.

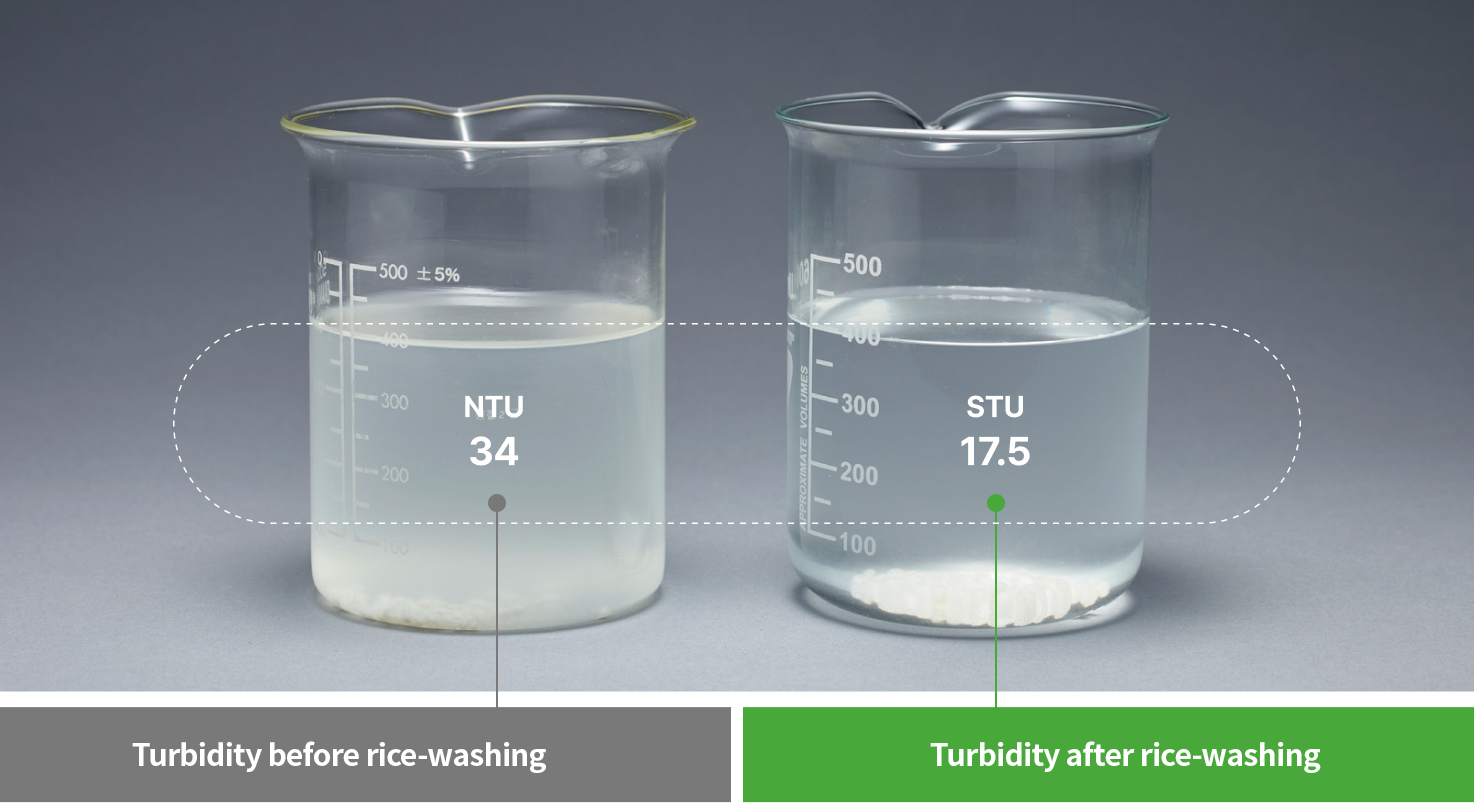

Comparison Before and After Rice Washing

- Comparison of whiteness and turbidity before and after rice-washing

| Sample | Turbidity (NTU) |

Whiteness (STU) |

Moisture content of sample |

|---|---|---|---|

| Before rice-washing | 34 | 39.5 | 13.6% |

| After rice-washing | 17.5 ▼ | 42.3 ▲ |

Turbidity may vary depending on the type of rice.

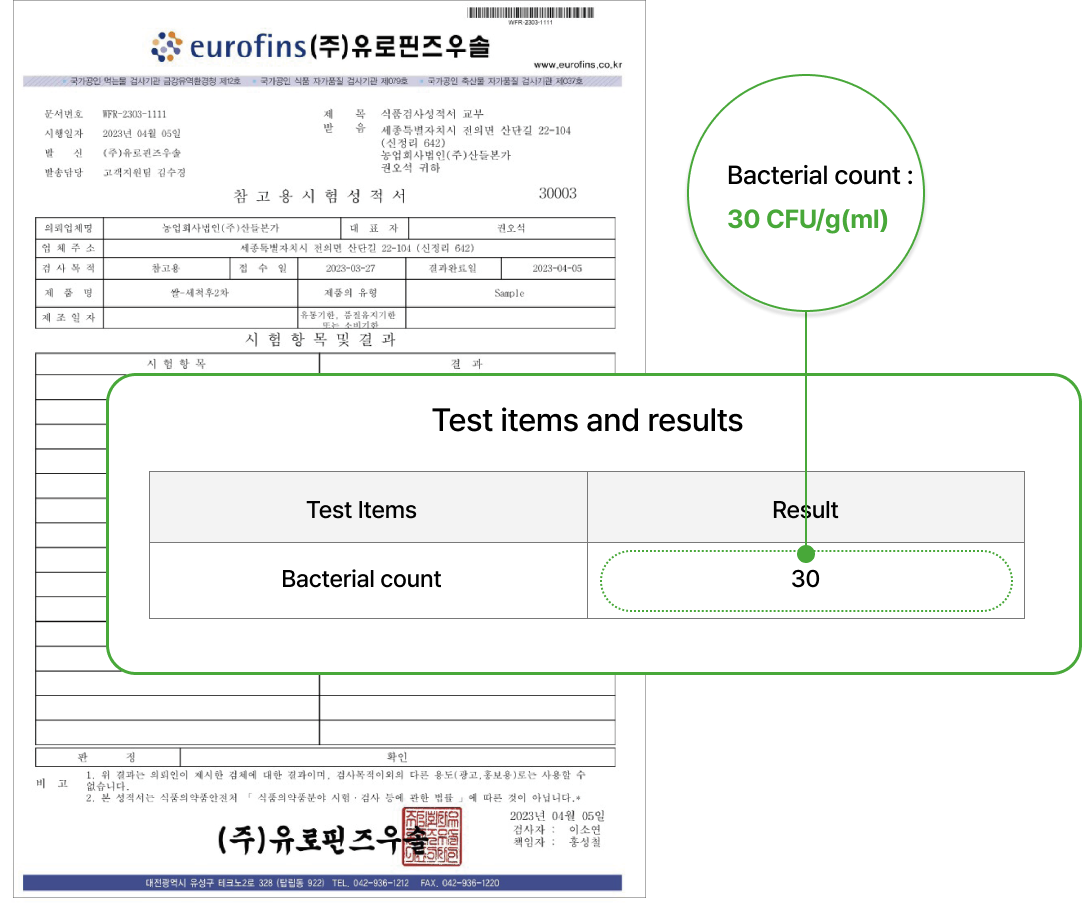

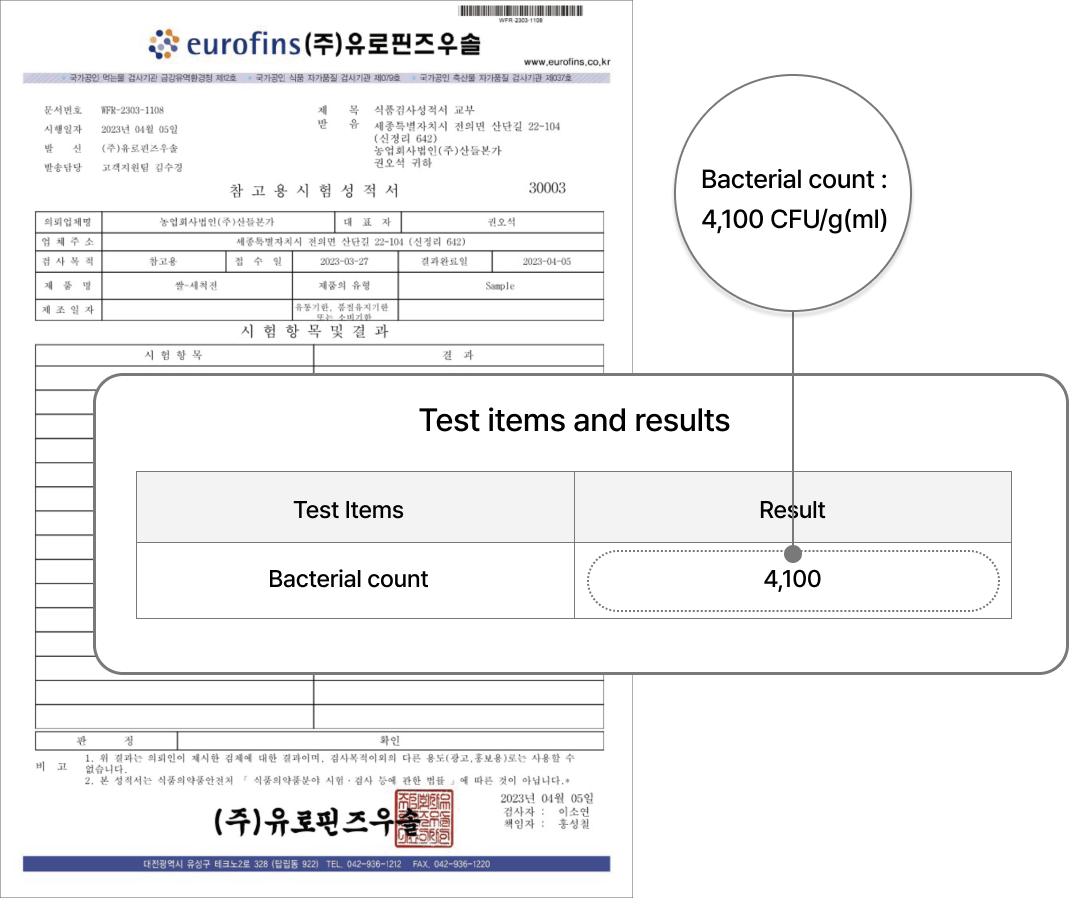

Test Report of General Bacteria Change

Before rice-washing

After rice-washing